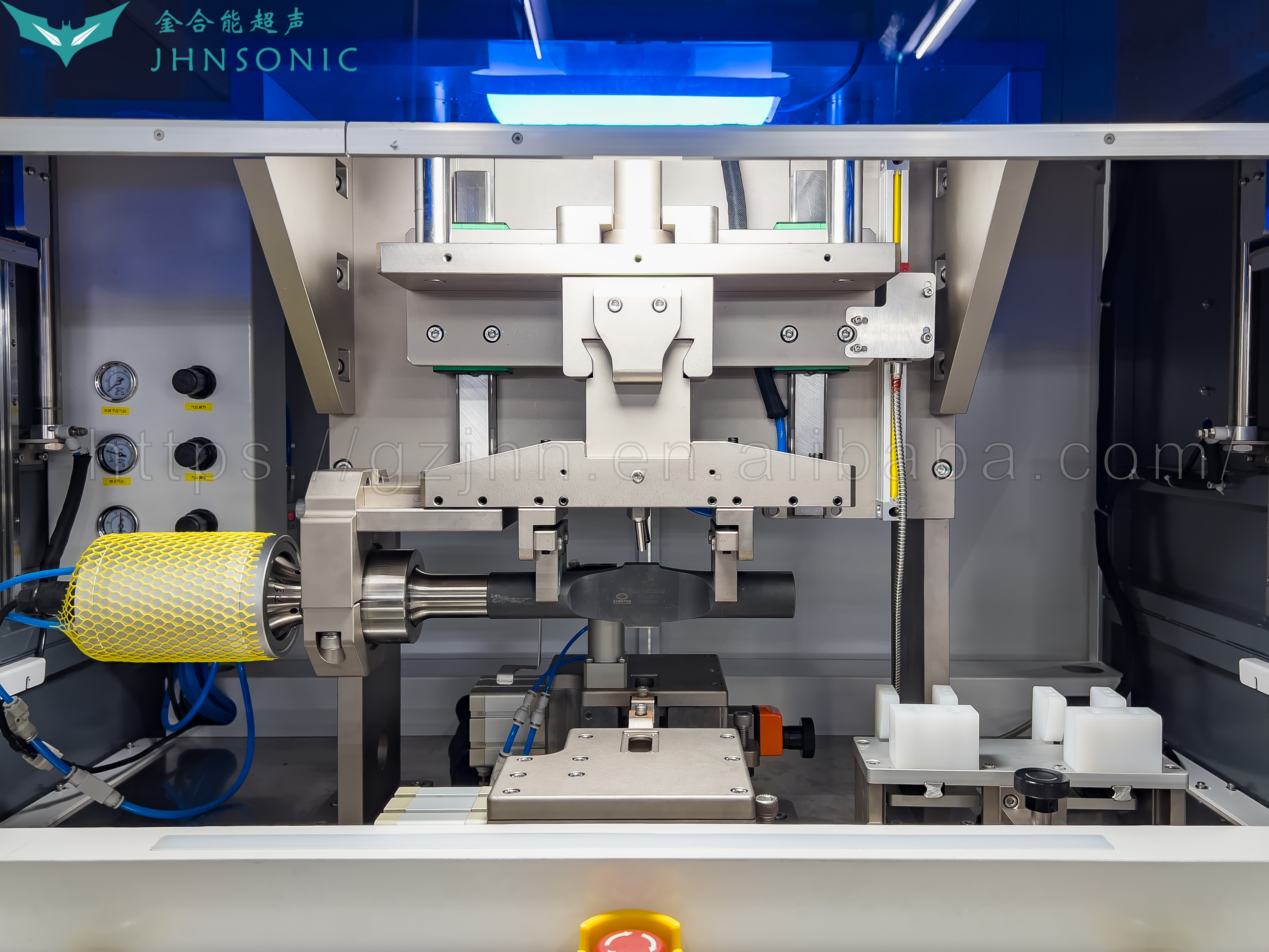

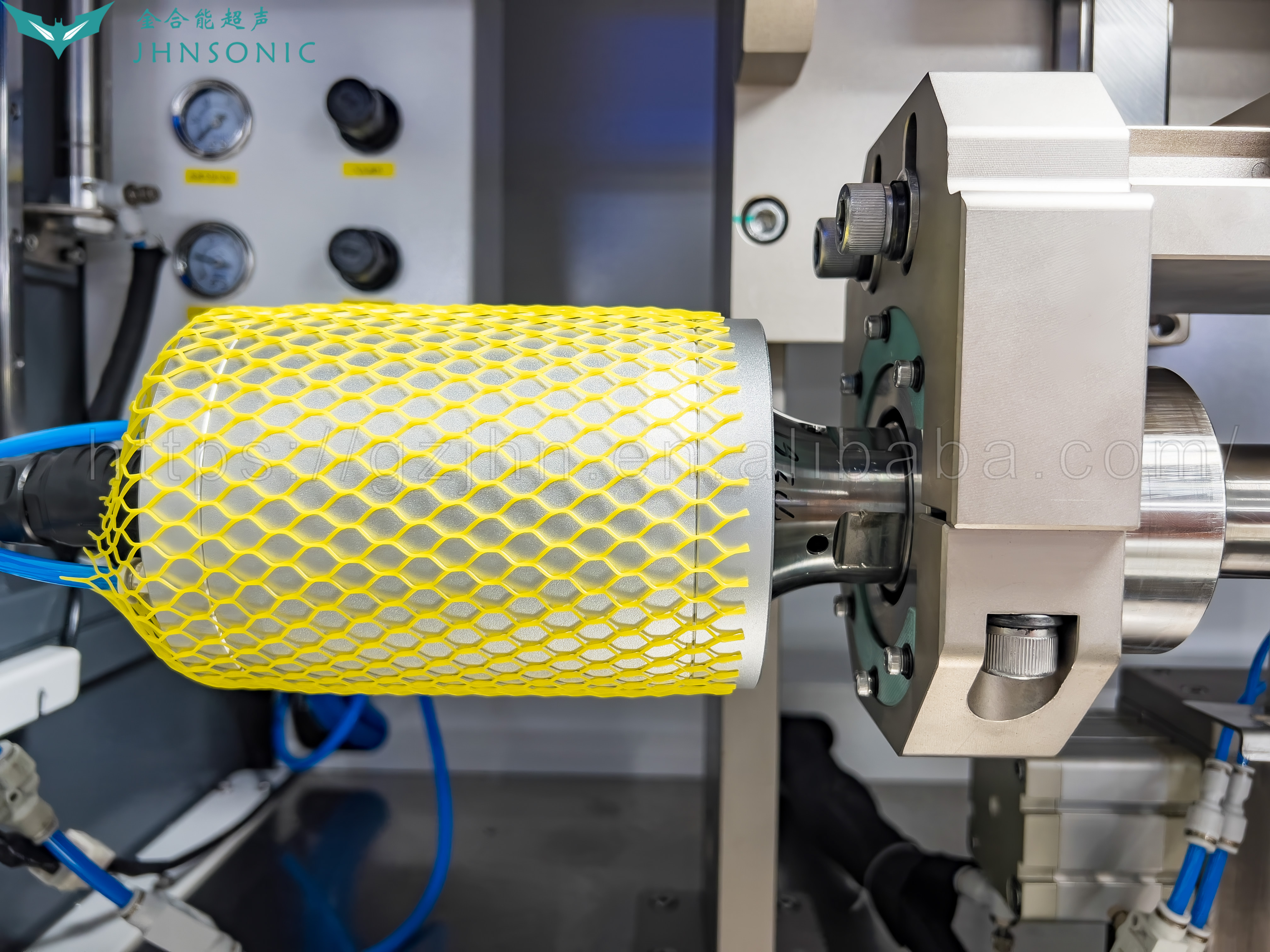

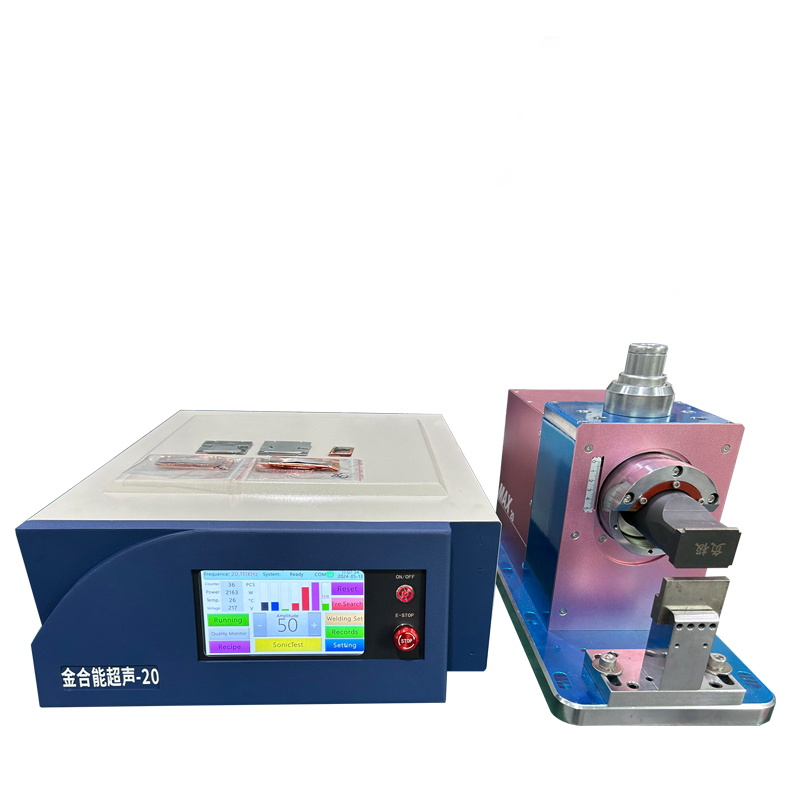

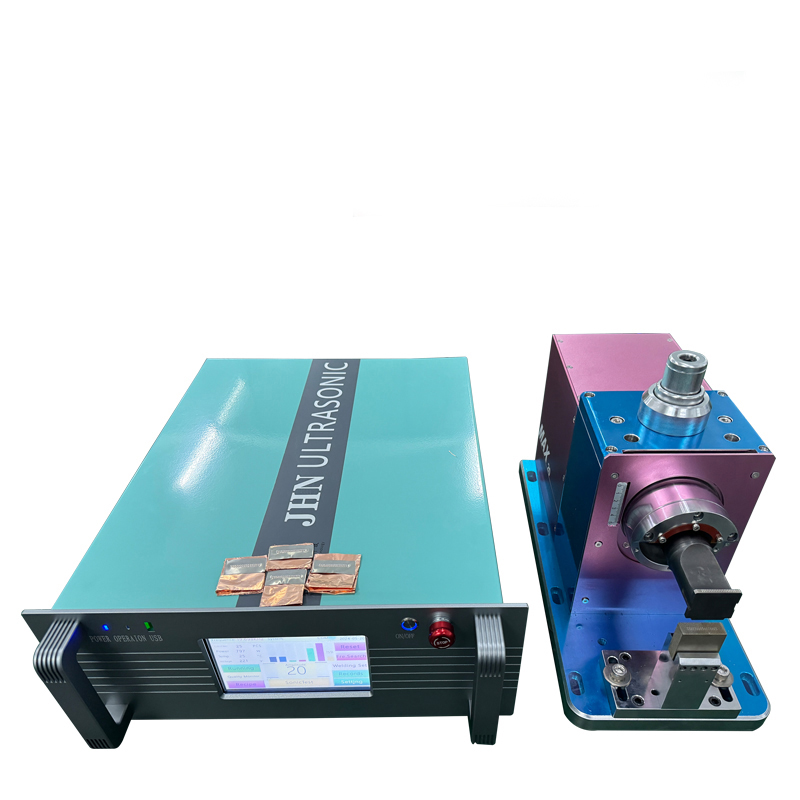

High-quality ultrasonic transducer with strong power and stability

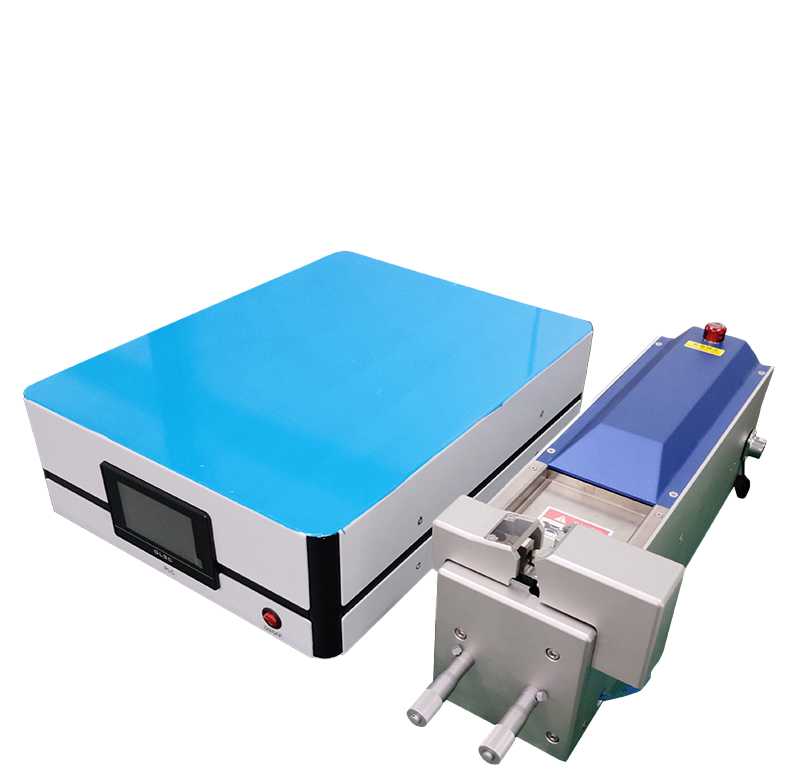

Excellent conductivity with near-zero resistivity

Capable of welding oxidized or plated metals

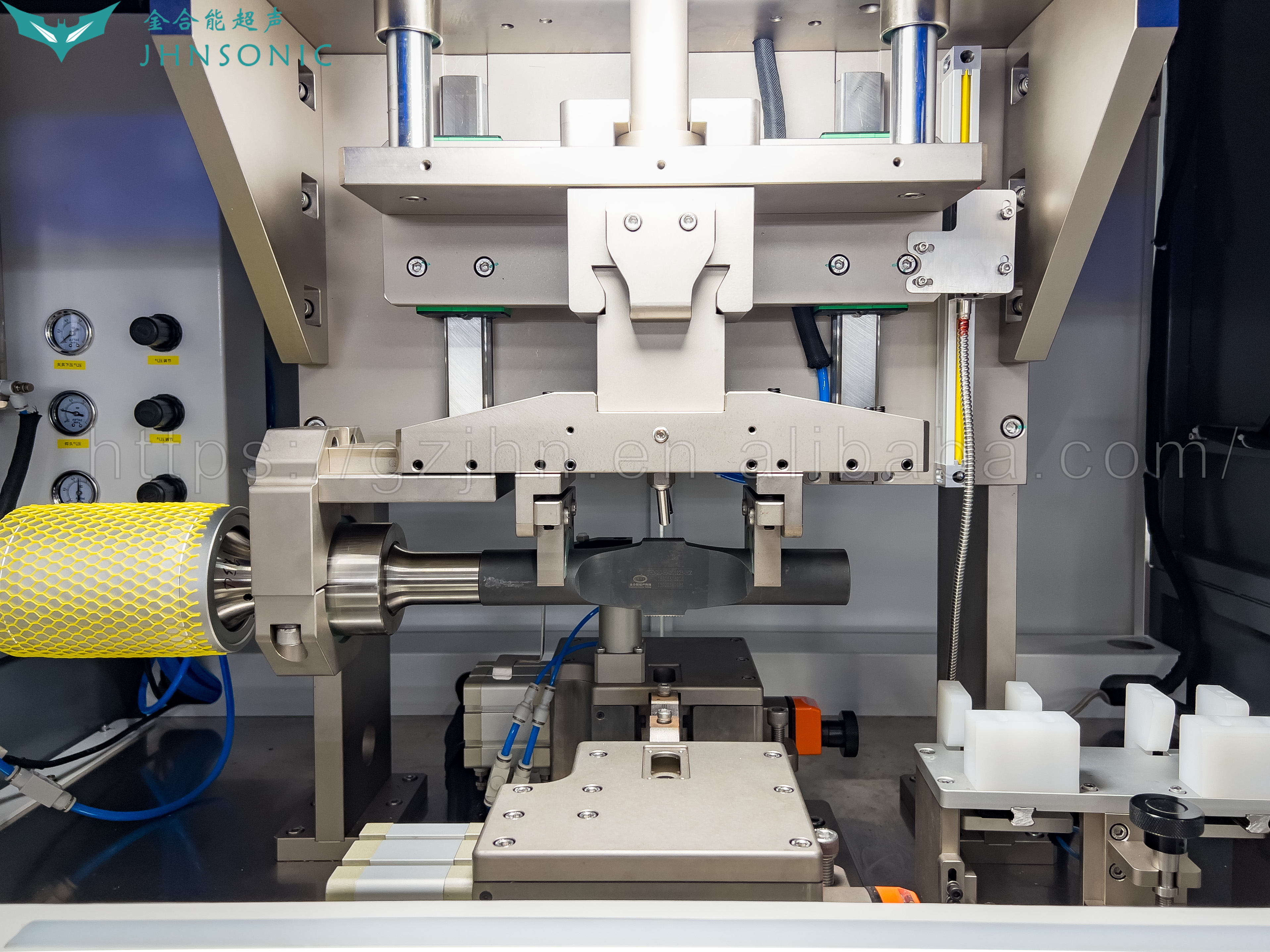

Short welding time, no additional flux/gas/solder required

No welding sparks – environmentally safe operation

Stepless amplitude adjustment reduces component replacement

Low energy consumption, high efficiency, no distortion

Material doesn't melt – maintains metal properties

Suitable for low-oxidation or plated metal surfaces